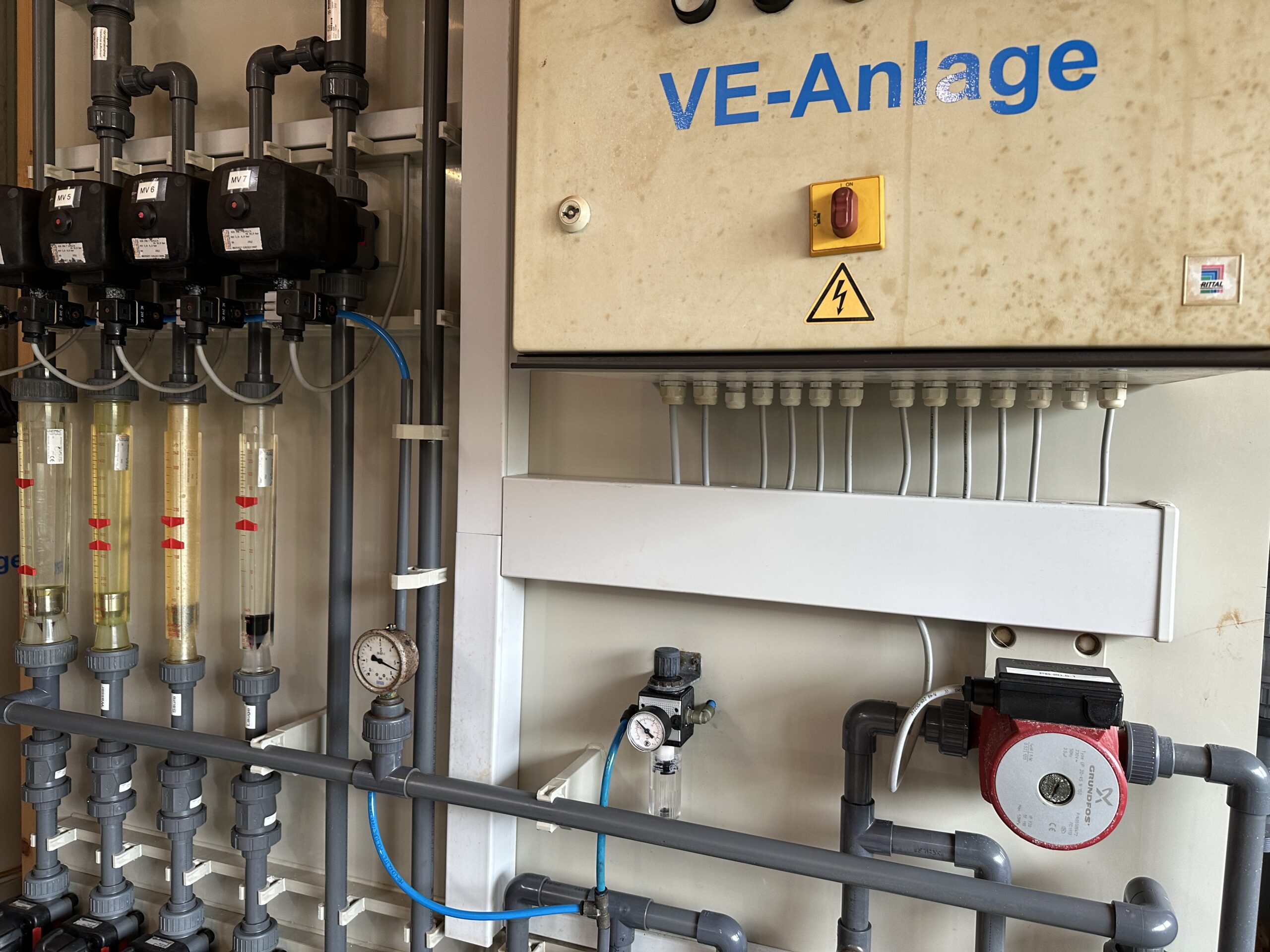

Ion exchanger system fault

Ion exchanger systems are generally resilient systems. Nevertheless, there are also typical error patterns in various applications, ion exchanger system malfunction, which are not always avoidable:

- Fault: Precipitations in the ion exchanger

In proper operation, an ion exchanger separates the regeneration agents or the conditioned elements again. In the case of cation exchangers regenerated with hydrochloric acid, for example, the loading from the feed can cause the elution of H+. However, this has a direct influence on the pH value. This means that the pH value within the ion exchange column shifts and becomes more acidic by up to -4 pH points. It can happen that elements dissolved in the feed (e.g. alkaline dissolved aluminum) enter the precipitation area within the exchanger. This results in precipitation in the exchanger, which can also block it completely. If the input feed operates under controlled and known conditions, this can be taken into account in the design, but may not (or no longer) be prevented if conditions are constantly changing. In addition to mining degradation of the ion exchanger, there may be chemical options depending on the precipitation, but these may take a long time. - Fault: Ion exchanger resin wear, change of ion exchanger or resin replacement

Over the years, anion exchangers in particular lose their functional groups as intended and a resin replacement becomes necessary after 4-7 years. Other reasons for an earlier resin change can be, for example: Biological infestation, oxidative attack, oiling. If there are no precipitations in the exchanger and the ion exchanger system has already been prepared for resin replacement during its manufacture and installation, resin replacement does not represent a significant effort. Special pumping and draining equipment is available for resin exchange, that makes the work involved manageable. In some applications, a so-called star distributor is installed at the top of the ion exchanger cartridge, which must be complexly dismantled, as the internal star distributor is significantly larger than the opening and this is difficult to do without special tools. However it should absolutely be avoided to replace the resin bed at sight using a folding rule, as the ion exchangers change their volume during operation and, in unfavorable constellations, this can cause the ion exchanger cartridge (also a demineralization cartridgeto burst. Furthermore, not all resins can be used directly from the delivery form, e.g. a not inconsiderable ion exchanger odor can be emitted from the cartridge, which can pollute an entire factory hall. - Process engineering problems with the ion exchanger system as a fault

When the ion exchanger system gets older and the original level of training on the system is no longer available, at least after a change of personnel, it can happen that individual components on the system are no longer maintained to a sufficient extent. If a venturi nozzle or vacuum pump is installed in the system, this is a frequent source of faults without maintenance if the nozzle becomes contaminated due to deposits or foreign bodies, preventing chemicals from entering the regeneration cycle. Without further monitoring technology, the ion exchanger system then reports proper regeneration, but it is still (at least partially) unregenerated and then does not achieve the required conductivity value, or only for a short time. In this case, for example anexternal maintenance of the ion exchanger systemcan be helpful.

Your problem with an ion exchanger system is not listed here? Please contact us without obligation. We can help you further.