Germanium (Ge), a semi-metal with fascinating properties, is an indispensable component of modern technologies – from optoelectronics and infrared cameras to fiber optic cables and catalysts. Demand is constantly increasing, but availability is limited and extraction is often energy-intensive. In view of this fact, the efficient recovery of germanium from industrial process and waste water is increasingly coming into focus. At Decker Verfahrenstechnik, we are working intensively on solutions that not only protect the environment but also make economic sense. A key technology for this is the use of special ion exchange resins.

Germanium – a critical raw material at a crossroads: As a strategic raw material, germanium is on the list of many countries. Its unique semiconductor properties and its transparency to infrared radiation make it irreplaceable. However, the main source is often by-products of zinc and copper production, which makes its availability volatile. Industrial processes that use germanium often generate germanium-containing wastewater, which until now has either been costly to dispose of or treated with low efficiency. The potential to recover this valuable element from these streams is enormous – both from an environmental and economic perspective.

The challenge: Germanium in aqueous solutions The targeted removal of germanium from aqueous solutions is more complex than it might appear at first glance. Germanium is not usually present in water as a singly charged ion, but as neutral germanic acid (H₂GeO₃) or its deprotonated forms. Conventional ion exchangers are ineffective here. A special chemical “scavenger” technology is required.

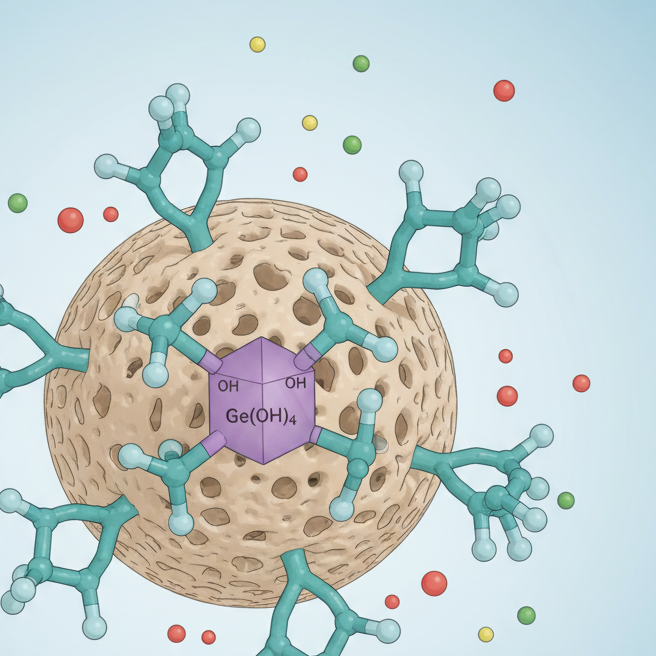

The solution: chelating ion exchange resins. This is where specialized chelating ion exchange resins come into play. These resins are not just simple ion “magnets”, but have specific functional groups that can bind germanium in a targeted and highly selective manner. The most effective functional group for germanium is N-methylglucamine (NMG).

These NMG groups act like a chemical “claw” (the term “chelate” comes from the Greek word for crab) that molecularly encloses the germanium acid and forms a stable complex. As a result, the germanium is firmly bound to the resin, while other unbound ions simply flow through the system with the water flow. This enables extremely selective separation even at low germanium concentrations and in complex mixed waters.

The process: from removal to recovery The process with NMG resins for germanium recovery is efficient and consists of several steps:

- Adsorption: The industrial water containing germanium is passed through a column filled with the NMG resin. As the water flows through, the germanium is specifically bound to the resin.

- Washing: After loading the resin, unbound impurities and residual water are rinsed from the resin column.

- Elution: The bound germanium is then selectively dissolved from the resin using a special elution solution. This breaks up the chelate complex and the germanium is released from the resin in a highly concentrated form in a germanium compound.

- Resinregeneration: After elution, the resin is washed and is then fully functional again for the next adsorption cycle. The resin can therefore be used over many cycles.

Advantages of germanium recovery with NMG resins:

- High selectivity: The NMG resin binds germanium very specifically even at low concentrations and in the presence of other ions.

- Cost-effectiveness: The process enables the recovery of a valuable raw material, reducing the cost of new production and generating revenue through the sale of recycled materials.

- Environmental protection: The removal of germanium from waste water prevents its release into the environment and minimizes the need for primary raw materials.

- Concentration: Germanium can be transferred from large volumes of water into a small, highly concentrated volume, which simplifies further processing.

- Robustness: The resins are robust and durable, which leads to stable process sequences.

Decker Verfahrenstechnik: Your partner for sustainable solutions At Decker Verfahrenstechnik, we specialize in the development and implementation of tailor-made solutions for water treatment and resource recovery. We will be happy to provide you with comprehensive advice on the options for removing germanium from your industrial water and recycling valuable resources sustainably. With our expertise and state-of-the-art ion exchange technology, together we can make an important contribution to the circular economy. Please bear in mind that such technologies are not possible with industrial water. A technical assessment of the specific application is therefore always required first.

Contact us today to find out more about how we can help you recover germanium efficiently and optimize your processes!