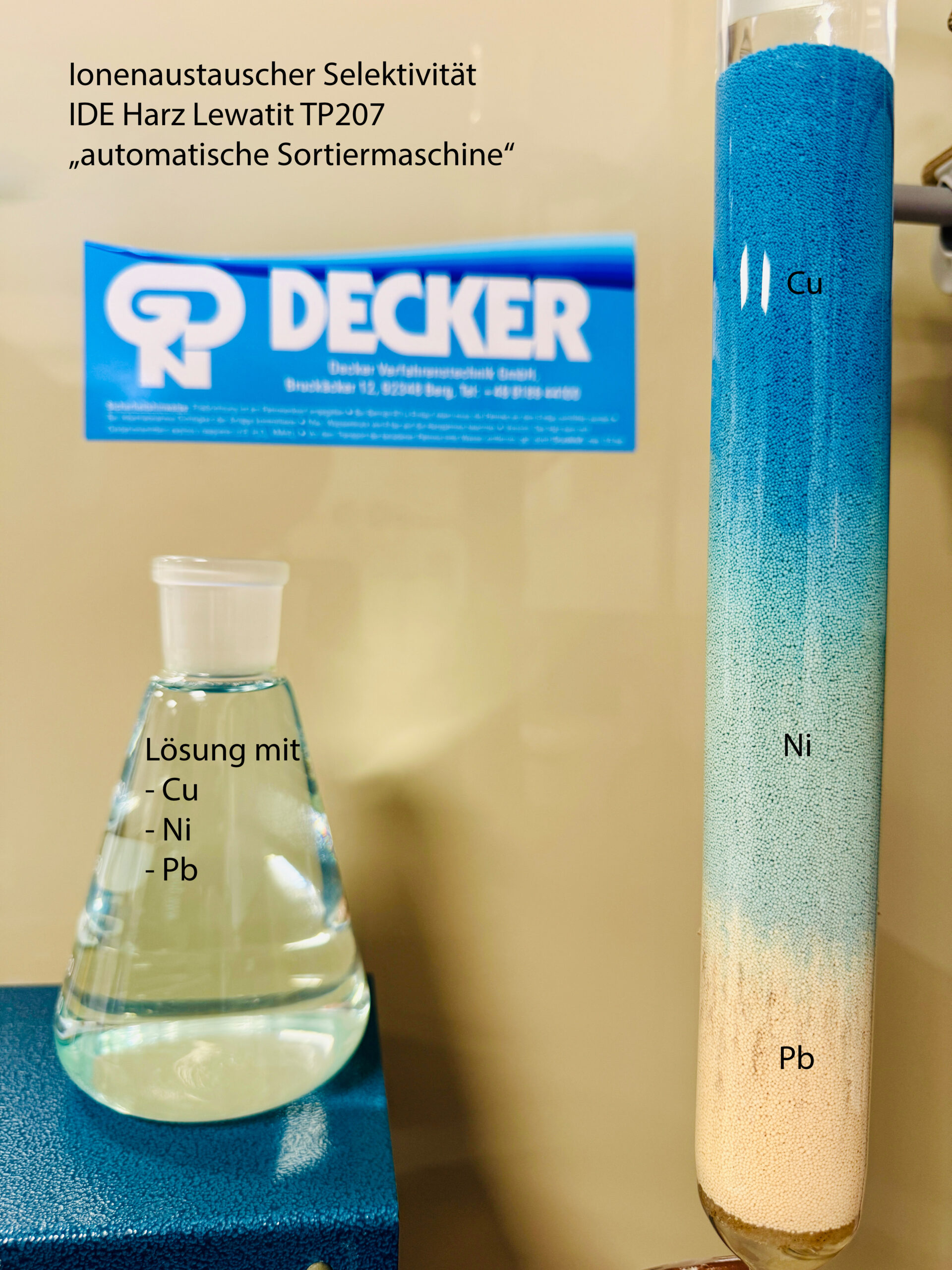

Ion exchanger selectivity

The ion exchanger selectivity or selectivity series describes the affinity of the binding of various ions to an ion exchanger. An ion exchanger is not a filter that contaminates itself indiscriminately with the incoming ions, but an “automatic sorting machine” for ions in order of selectivity.

To understand an ion exchanger, it is first important to preload an ion exchanger. This cannot be “0” as with a filter that should release as little as possible, but always corresponds to the pre-loading of the ion exchanger. This can be, for example: H+, Na+, Ca+, K+ or the NH4 form, for the anion exchangers the OH- (or correctly free base for the weakly basic anion exchanger) or Cl- form or for weakly basic exchangers additionally the NH3 or the protonated ammonium form. In the simplest case, full demineralization via a mixed bed ion exchanger in a demineralization cartridge, the strongly acidic cation exchanger is in the H+ form in its original condition and the strongly basic anion exchanger is in the OH- form in its original condition. In this form, the resin in the appropriate pH range is already able to exchange this pre-load for another charge carrier as part of chemical equilibrium reactions with the functional group of the respective ion exchanger. The further to the left a substance is in the row, the more affinity the ion exchanger has for a binding if the other frame parameters(pH value, temperature, etc.) fit:

The selectivity series for strongly acidic cation exchangers (sulphonic acid exchangers) SAC is as follows:

Al3+ > Cr3+ > Fe3+ > Ba2+ > Pb2+ > Ca2+ > Ni2+ > Mg2+ > K+ > NH4+ > Na+ > H+

The selectivity series for weakly basic anion exchangers (tertiary amine exchanger) WBA is as follows:

OH– >> SO42- > HSO4– > I– > NO3– > Br– > Cl– > F–

The selectivity series for strongly basic anion exchangers (quaternary amine exchanger) SBA is as follows for anions

(without anion complexes):

SO42- > HSO4– > I– > NO3– > Br– > Cl– > HCO3– > HSiO3– > F– > OH–

(with cyanide anion complexes)

Co2+ > Hg2+ > Fe2+ > Cu2+ > Ni2+ > Ag+ > Au+ > Cd2+

The selectivity series for weakly acidic cation exchangers (iminodiacetic acid exchangers, IDE exchangers) WAC is as follows:

Fe3+ > Cu2+ > TiO2+ > VO5+ > UO2+ > VO2+ > Hg2+ > Pb2+ > Sc3+ > Ni2+ > Zn2+ > Co2+ > Cd2+ > Fe2+ > Be2+ > Al3+ > Mn2+ > Ca2+ > Mg2+ > Sr2+ > Ba2+ > Na+ > K+ > Cs+

The selectivity series for special exchangers such as thiourea exchangers is as follows:

Hg2+ > Ag+ > Au+/3+ > Pt2+/4+ > Cu2+ > Pb2+/4+ > Bi2+ > Sn2+ > Zn2+ > Cd2+ > Ni2+

However, the process does not end with the one-time binding. During further loading of the resin bed, i.e. with the next liters of contaminated water, there is another binding in competition with the binding already formed. This means that if an incoming higher-selective ion Cu2+ passes an already bound lower-selective ion Ca2+, the higher-selective ion Cu2+ displaces the lower-selective Ca2+ and forms the binding, The low-selective ion is displaced and may form a further binding with an even lower-selective H+ ion. This creates the effect that the highest selective ions accumulate in the upper area of the ion exchanger resin bed when flowing through the ion exchanger cartridge, the medium-selective ions in the middle area of the ion exchanger resin bed and the low-selective ions in the lower area of the ion exchanger resin bed.

In the example picture, a solution is prepared with the ingredients Cu2+ Ni2+ Pb2+

The ion exchanger is then loaded with it and the various zones are formed in an ion exchanger until the first breakthrough (due to the pH value in this case Pb instead of Ni).

If the capacity in the ion exchanger resin bed is now completely exhausted, the binding does not simply stop, but continues according to the selectivity series. In concrete terms, this means that the upper range of the highest selective ions continues to grow, the range of the medium selective ions is partly displaced downwards but continues to grow and the range of the low selective ions is displaced even further downwards in the ion exchanger resin bed and would also like to continue growing – but cannot do so due to the lack of capacity. As a consequence, only a disproportionately large number of the low-selective ions is released in accordance with the selectivity series, and the exhausted ion exchanger is thus overrun. In the mixed-bed ion exchanger in a mixed-bed polisher or in a demineralization cartridge or VE-cartridge, these are usually silicates forming undesirable deposits, dissolved gases or corrosive chlorides. In the example picture, this would mean that the loading continues until the Ni and Pb are completely displaced by the Cu, i.e. the resin is completely blue. Only in this state does the inlet correspond to the outlet and the ion exchanger is completely inactive. Ion exchanger regeneration is required to bring the ion exchanger back to a functional state.

It is therefore often advisable to design a system with 2 ion exchanger cartridges in series, whereby the capacity exhaustion of the first one is defined as the exchange criterion, e.g. by conductance in µS/cm or by analysis.

Typical limits of the conductance for the replacement of the first ion exchanger cartridge are:

- Semiconductor < 0.1 µS/cm

- Hard chrome plating < 3 µS/cm

- Electroplating < 20 µS/cm

- Anodised< 30 µS/cm

- Hot-dip galvanizing < 50 µS/cm

- Forklift water or battery water during filling: < 30 µS/cm

If the conductance of an ion exchanger cartridge is used as a criterion, it generally remains stable over a long period of time until it increases exponentially towards the end of its service life. It is therefore useful to replace the exchanger cartridge at the first sign of an increase, as a breakthrough to the downstream exchanger can already be expected at this point (especially dissolved gases and silicates/silicic acid not visible in the conductance).